|

History first and fun later.

Today, we drove to Danville, Kentucky. It was about 30 minutes south of the campground. Danville was where Kentucky was "birthed". The first state constitution was signed here.

The square included several replica buildings. The courthouse of where original founding constitution for the State of Kentucky was signed, a jail, meeting house/church, tavern, post office, and school house.

There are many historical buildings on the walking tour.

Oh! It seems they have a very unusual way to describe parking spots along the street.

I can only guess that the "stall" is the lined area but wow is it time to update the terminology?

Now for some fun. We had appointments for a tour of the Wilderness Trail Distillery. But first a little history: Straight Bourbon is regulated to how it is made and what is used in the process. The regulations came into effect when fake Bourbons started being produced which were not much more than flavored cheap vodka. If something is called Straight Bourbon it must be made of fermented grains and aged over 2 years in a barrel but if under 4 years the label must list its age. Flavored “Bourbon” can be aged as little as a few months. Now on to the tour.

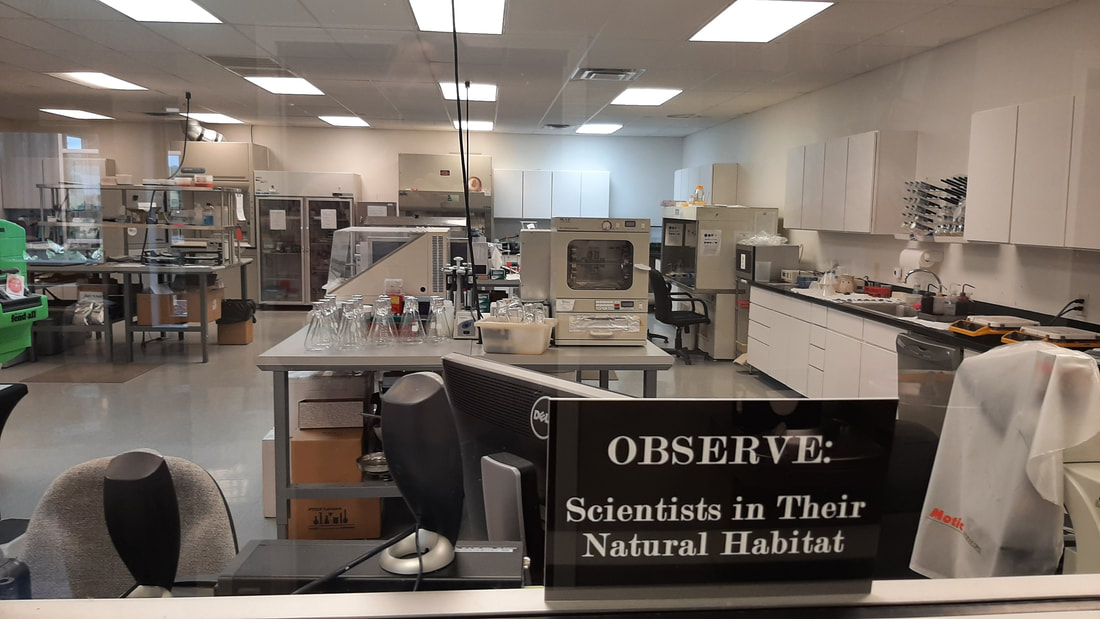

They are pretty new for a distillery. From 2003 to 2013, they were the brewing and distilling consulting scientists for a lot of the big distillers in the country. When a company had problems, they would send samples for Wilderness to process for solutions. They still have chemists to do that work but have expanded.

After doing that for 10 years, they decided to produce their own whiskey and soon had to move out of town to their current location. They have 163 acres from a former cattle ranch where the current facility is housed in a dozen large buildings.

Our guide gave us a quick rundown on the history of the company and then took us to see the two 10,000 gallon cookers and five 20,000 gallon fermentation tanks. That is a lot of future alcohol.

Grains like corn, barley, and rye are ground to a powder and mixed with water put in a cooker. The cooker gets the temperature of the mixture up and yeast is added. Then the mash is moved to the fermenter tanks to make alcohol.

One of the cookers was open for us to look down and see mash being prepared. The smell was incredible. It was kind of like a mixture of the smell of breads being made.

The tops of the fermentation tanks are open to allow for heat and gasses to escape. It was pretty amazing seeing the tanks bubbling away not from heat but the yeast working.

Next we moved to the still and condensing room. To increase the alcohol content, the mix is moved from fermentation to a column still. These things are big. The ones used by this distiller are over 3 stories tall. The alcohol drips down and then evaporates returning to the top repeating the process. Copper filters at each level screen out the mash. It makes several trips until the content is over 150 proof and completely clear.

First, our guide pulled off some of the liquid and poured a small amount in our hands. He told us to smell and then rub our hands for a couple of seconds and smell again. As we did, the odor changed till it smelled like yeast bread. Then we were able to taste the clear liquid. WOW! That was strong.

They decided to have a little fun with the process. You can see the purity as the alcohol pours over this device.

The 6th rick house is under construction but there is room for a dozen more if needed. Rick houses are where bourbon is stored to age. They have bourbon up to 8 years old but plan to age much longer as they have product.

A few more facts about bourbon:

The barrel is the primary element in making bourbon and its flavor. So the wood type used and the charring of the inside of the barrel is essential for the flavor of the liquor. Barrels can only be used once for Bourbon production and are sold to other companies to give an interesting flavor to products. The best Tabasco, Family Reserve, is aged in old bourbon barrels to give it a special flavor

Barrels are stored in the Rick houses. Once filled the 50 plus gallon barrels weight over 500 pounds.

The entire interior structure of a Rich house is made from wood to limit sparks. The reason for this is the “Angels Share” which is the water vapor with some alcohol that will seep out of barrels as the bourbon ages.

The mix of odors was overwhelming. Most of these buildings are 6 or more stories tall and completely filled with barrels. A single building can have thousands of barrels aging for over 4 years and many times 8 years or more. That is a long wait for a product to be ready to sell.

Temperature of the house is maintained but lower and higher floors will have differences and this will change the development of the bourbon. The flavor and alcohol content is tested determine if the barrel is ready to be bottled. Tough job but someone has to do it.

0 Comments

Leave a Reply. |

AuthorWe are a couple who have started on a new adventure... Archives

February 2024

Categories |

RSS Feed

RSS Feed